From 2D Inspection to 3D Measurement: DEPZ Prioritizes Stereo Disparity with Machine Learning

In Q1 2024, DEPZ decided to focus on stereo disparity estimation using machine learning. The goal is to turn inspection into measurement—enabling repeatable 3D assessment of defects and geometry deviations under challenging industrial conditions.

What We Learned from Early Pilots

During initial vision pilots, one conclusion became clear: in many cases, it is not enough to see a defect—we must measure it against tolerances.

Large-format products can exhibit:

- Slow warpage across wide surfaces

- Small but important deviations at edges and joints

- Defects whose severity is defined by depth/height rather than appearance

This naturally led DEPZ toward stereo vision and depth reconstruction as a core capability.

Why Disparity Is the Technical Bottleneck

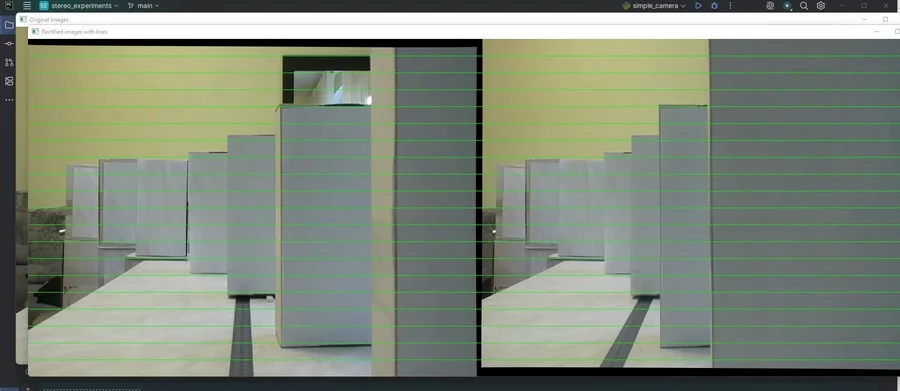

Depth from stereo starts with disparity: matching points between left and right images. In controlled demos, many methods work well. In real production settings, the problem becomes harder due to:

- Low-texture surfaces (smooth plastics)

- Reflections and specular highlights

- Illumination differences across large areas

- Motion, vibration, and throughput constraints

If disparity is unstable, depth becomes unstable—and measurement becomes unreliable.

Why Machine Learning Approaches Are Promising

In Q1 2024, DEPZ prioritized research into ML-assisted disparity estimation, including hybrid approaches combining classical geometry with learning-based matching. ML methods can improve robustness by:

- Learning matchability patterns on low-texture surfaces

- Handling repeated patterns and ambiguous regions more gracefully

- Adapting to specific industrial domains through curated datasets

- Providing more consistent results in regions that matter for QA decisions

What We Are Actually Building (Not Just "a Model")

DEPZ's disparity program is treated as a full engineering stack:

- Data Pipeline. Dataset collection across multiple surface states and lighting setups; defect and geometry scenarios representative of production; labeling strategy aligned with measurable outcomes (not just visuals).

- Calibration Stability. Procedures for camera calibration and re-calibration; checks for drift and mechanical stability over time.

- Evaluation Harness. Repeatable tests on reference objects and known geometries; metrics that reflect industrial requirements (repeatability, failure modes, confidence).

- Deployment Constraints. Throughput and latency targets; reliability under long runtimes; predictable behavior when conditions degrade.

Expected Outcome

The objective is to create a depth core that can power:

- In-line inspection and metrology

- Robotic handling and automation use cases

- Future product-level stereo devices and software

This is a foundational investment: once disparity and depth become reliable, a large class of automation problems becomes easier and more scalable.