Pre-Series Samples Pass Durability and Calibration Stability Testing

In February 2025, DEPZ pre-series camera samples underwent rigorous durability and calibration stability testing. The cameras passed 20 drop tests in various configurations along with thermal cycling and other stress tests. Engineers validated depth map quality through visual inspection and analytical assessment.

Why durability testing matters for stereo cameras

Unlike consumer cameras, industrial stereo cameras must maintain precise calibration even after mechanical stress. A misalignment of just a few microns between the optical centers can degrade depth accuracy significantly. DEPZ designed its pre-series validation program to stress-test both physical durability and calibration retention.

The test program

Each pre-series sample completed a comprehensive battery of tests designed to simulate real-world industrial conditions:

- Drop testing (20 cycles). Cameras were dropped from standard heights across multiple orientations—front, back, sides, and corners—to validate housing integrity and optical alignment retention.

- Thermal cycling. Repeated heating and cooling cycles to test material stability, bonding integrity, and calibration drift under temperature changes.

- Vibration stress. Simulated transport and operational vibration conditions to ensure components remain secure and aligned.

- Lens-side impact. Targeted drops on the optical side to test lens mount resilience and protective housing effectiveness.

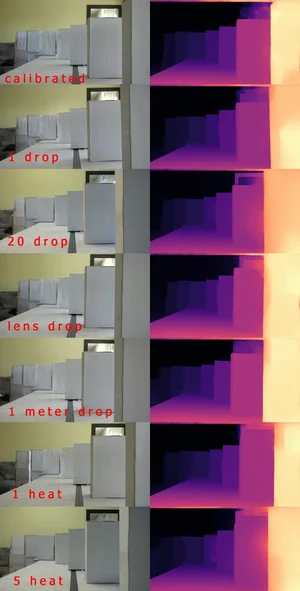

Depth quality validation

After each test phase, engineers assessed depth map quality through two complementary methods:

- Visual inspection of rectified stereo pairs to verify epipolar alignment

- Analytical comparison of depth maps against ground-truth reference scenes

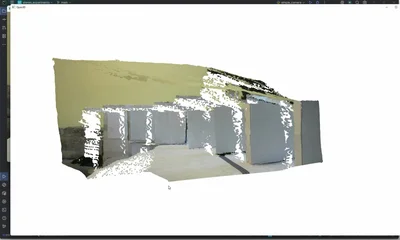

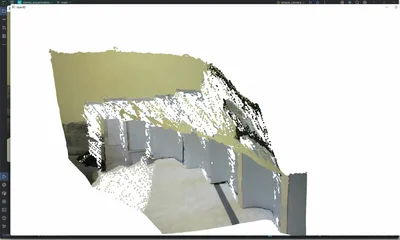

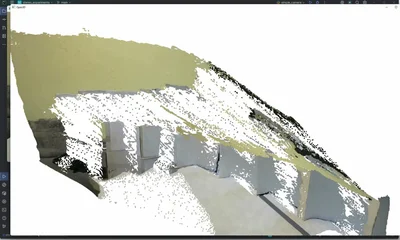

- 3D point cloud reconstruction and visual inspection from multiple angles

- Quantitative metrics: RMSE of depth values, edge sharpness, and noise levels

Test results and next steps

The pre-series samples demonstrated strong calibration retention across all test conditions. Depth map quality remained within industrial tolerance thresholds even after 20 drop cycles and multiple thermal stress events.

- Finalizing acceptance criteria based on validated test data

- Documenting test protocols for production QA integration

- Preparing for pilot production run with qualified tooling

- Initiating early-adopter feedback collection program

These results confirm that DEPZ cameras are ready for demanding industrial environments where reliability and measurement accuracy are non-negotiable.